EDMS is CERN’s official Product Lifecycle Management (PLM) tool. EDMS’ functionality is integrated with and used in each stage of the PLM process. CERN’s flagship machines, such as the LHC, are taking full advantage of EDMS’ PLM capabilities, as seen in the examples below.

Design

The CERN Design Offices and EDMS

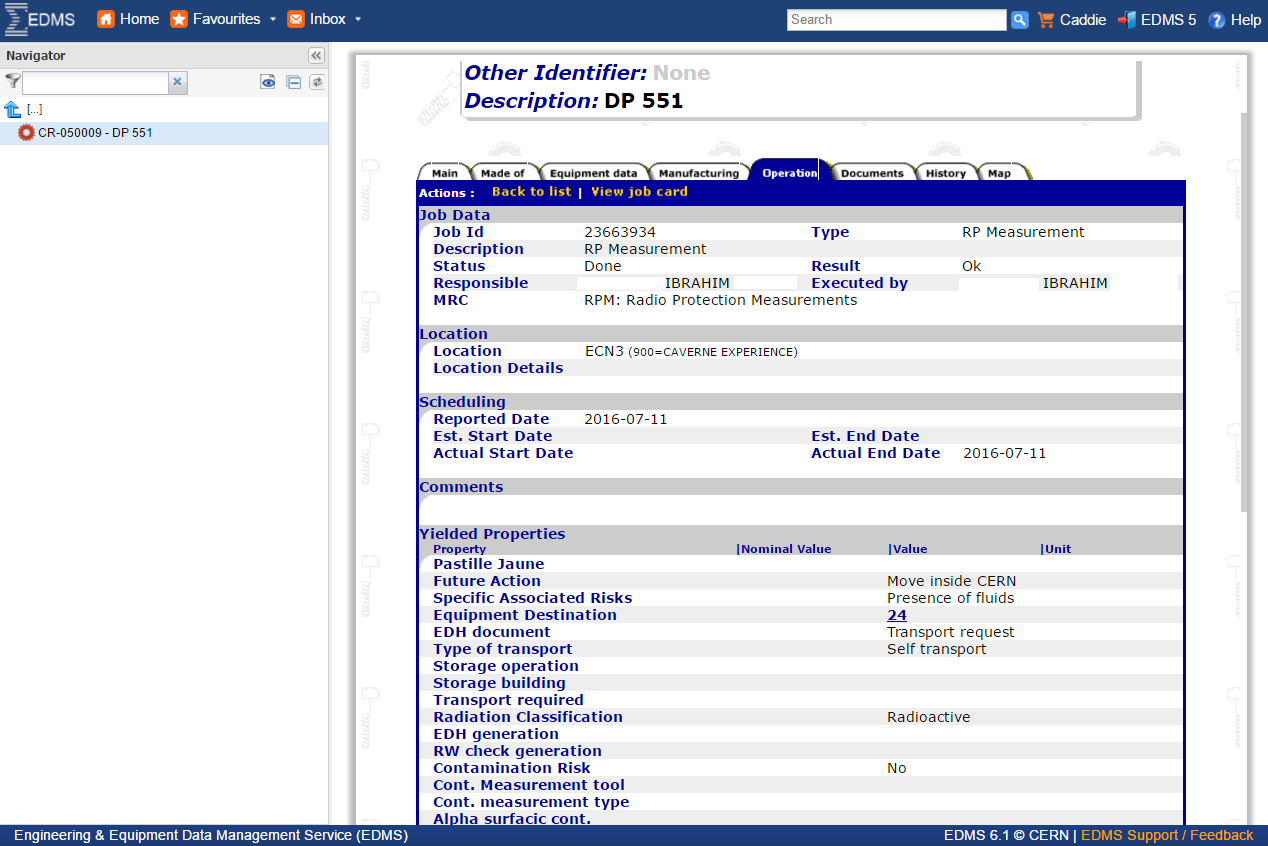

CERN has several internal design offices where designers draw components of CERN's accelerator complex and experiments. In their daily work they use CATIA for the 3D design and its corresponding 2D drawings. Once the design is ready, the drawings need to follow a release procedure which ensures their compliance with standards and functional specification given by the Project Engineer in charge. To achieve this, the 2D drawings are published from CATIA to EDMS/CDD via a CartWeb connector which in addition updates the standard CERN title block containing information about the drawing, its designer and design office, purpose, BOM, etc.

The release procedure of the drawings is carried out in CDD thanks to the control mechanism. In certain cases the drawings undergo an approval process – typically led by the Project Engineer – during which formal comments are gathered in the system regarding the design and its impact on other components. Once the approval is finished, the drawing can be used for several purposes such as tender, information, production according to the chosen label. CDD data is synchronized with EDMS and from the moment the drawing is published in CDD, it may be consulted via EDMS. Thanks to this the Project Engineers and Equipment Owners who initially ordered the design of components have a convenient and quick access to the 2D drawings, without having to use CATIA and SmarTeam.

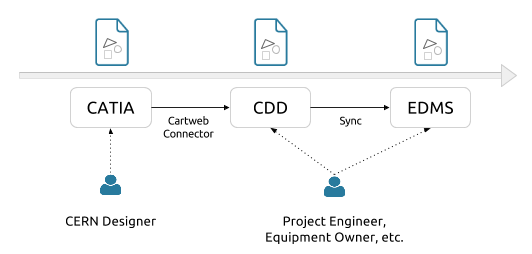

EDMS has a range of functionalities which support the described process. At early stages of the design, the drawing can directly be plotted from EDMS, and for example be shared for manual correction as part of the control process. Related drawings (e.g. one assembly composed of many parts) are grouped in EDMS drawing folders, which ease the collective plotting via EDMS caddie) or information consultation: via a single EDMS link. Drawing folders are also shared with CERN’s internal workshop where they serve as manufacturing orders.

CERN also outsources the design work. The design concept is prepared by CERN’s design office and is then shared with the contractor via EDMS. The contractor prepares the 2D drawings on their premise based on the received 3D models. These are then checked by the CERN responsible and send back for corrections if needed. The exchange of models and drawings is done via dedicated CAD Exchange EDMS structures with restricted access. This allows for traceability of information.

The LHC High Luminosity Upgrade and EDMS

EDMS and Infor EAM were the applications selected to serve the High Luminosity upgrade of the Large Hadron Collider (HL-LHC) as the standard tools for all technical data management and storage. The HL-LHC project team and the EDMS service worked together on ensuring that EDMS is fully integrated within the work processes of all HL-LHC work packages dealing with CAD design, equipment and/or technical documentation.

As a result of the successful implementation, the HL-LHC project was able to work on designs, technical documentation and equipment data via EDMS with all its 20+ partners throughout the world spanning form the US to Japan.

Manufacturing

Manufacturing

CERN Equipment Groups

Due to CERN’s physics and engineering nature, the Organization is responsible for both research on the basic constituents of matter and also developing the most complex scientific instruments in existence. The instruments, or machines, used at CERN are purpose-built particle accelerators and detectors. Accelerators boost beams of particles to high energies before the beams are made to collide with each other or with stationary targets. Detectors observe and record the results of these collisions. As the machines built by CERN are unique, the manufacturing process is often long and spans over decades, as seen in the example of the Large Hadron Collider below. It encompasses activities such as prototyping, testing and iterating over designs before the final components are produced. Each of those phases generates a wide spectrum of information such as technical specifications and design reports, 3D designs and 2D drawings, manufacturing bills of materials, test and calibration results, maintenance instructions and general project documentation. All of these are managed in EDMS and are linked to design items or physical assets.

The most recent example of EDMS’ integration within CERN’s manufacturing processes is the HL-LHC, closely following the approach of its predecessor, the LHC. EDMS’ approval process capabilities were used to draft and accept documents such as the work package breakdown specification of the project and its quality assurance procedures. On the technical side, EDMS is used on a daily basis directly on the on the 11 Tesla HL-LHC magnet prototyping workshop floors. Computers using EDMS are used by technicians and engineers to display the technical specifications, 3D designs and quality assurance procedures to be followed in their daily activities. Additionally, once a given step in the predefined workflow for the manufacturing of the given component is completed, the technicians documents their results in an EDMS document, done, again, directly on the workshop floor. Last but not least, EDMS’ flexibility in configuration and access rights management allow the HL-LHC quality assurance team to deliver tailor made EDMS environments for each work package and competence, whereby, for example, manufacturing technicians can focus on what’s important for them on the workshop floor and enter the data they need in an efficient way. This process is followed around the world, spanning from Europe and the USA to South Korea and Japan.

The system is used by all equipment groups in the Accelerators and Technology sector in conjunction with groups from the in conjunction with groups from the Occupational Health & Safety and Environmental Protection Unit (HSE), Experimental Physics (EP) and experiments such as ATLAS, AWAKE, CLIC and CMS. All those EDMS partners integrate EDMS in a manner similar to HL-LHC and ensure that the system is used to both store information and also deliver the correct content at the correct place

Maintenance documentation is often stored in EDMS via the EDMS Doc List functionality, as described in the Maintenance section of this page.

Furthermore, technical groups often use project structures and documents for stucturing and managing their technical documentation in EDMS. They view the information directly in EDMS, point to it via their websites or link it to their operational intranet websites using EDMS’s Doc List Functionality.

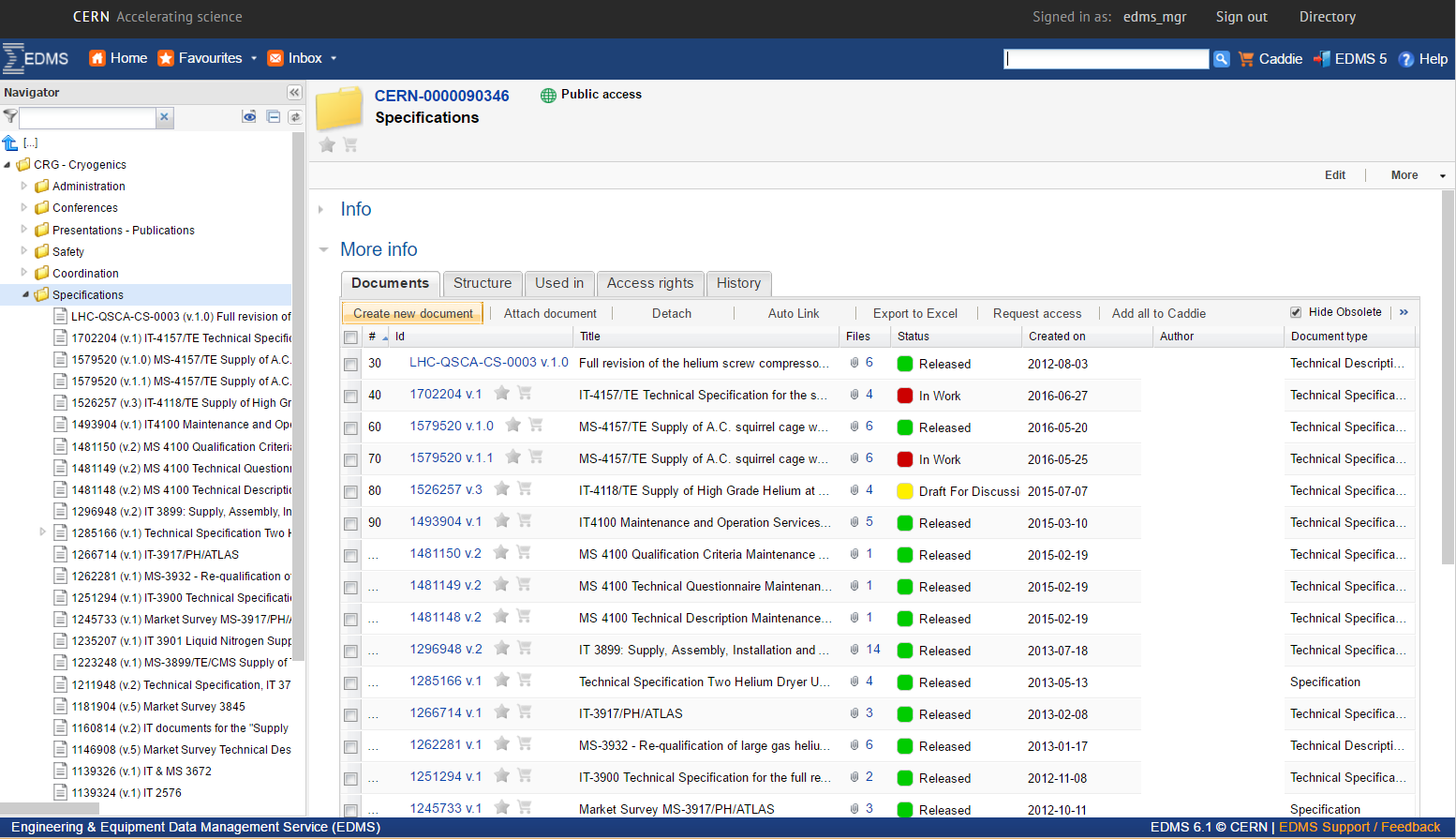

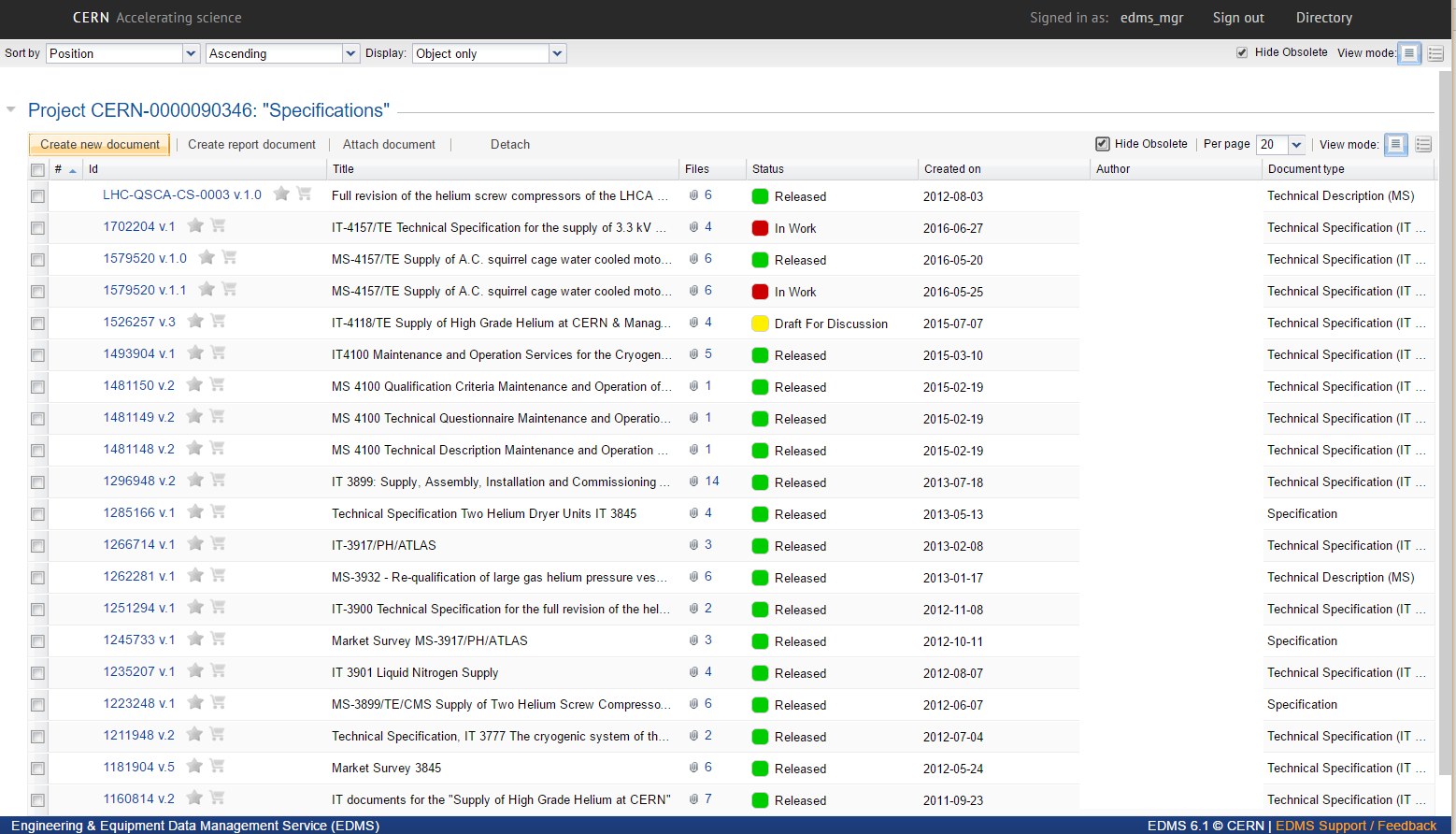

The EDMS structure of the Cryogenics (TE-CRG) Group

The same structure in an EDMS Doc List ready to be exported to an external web site

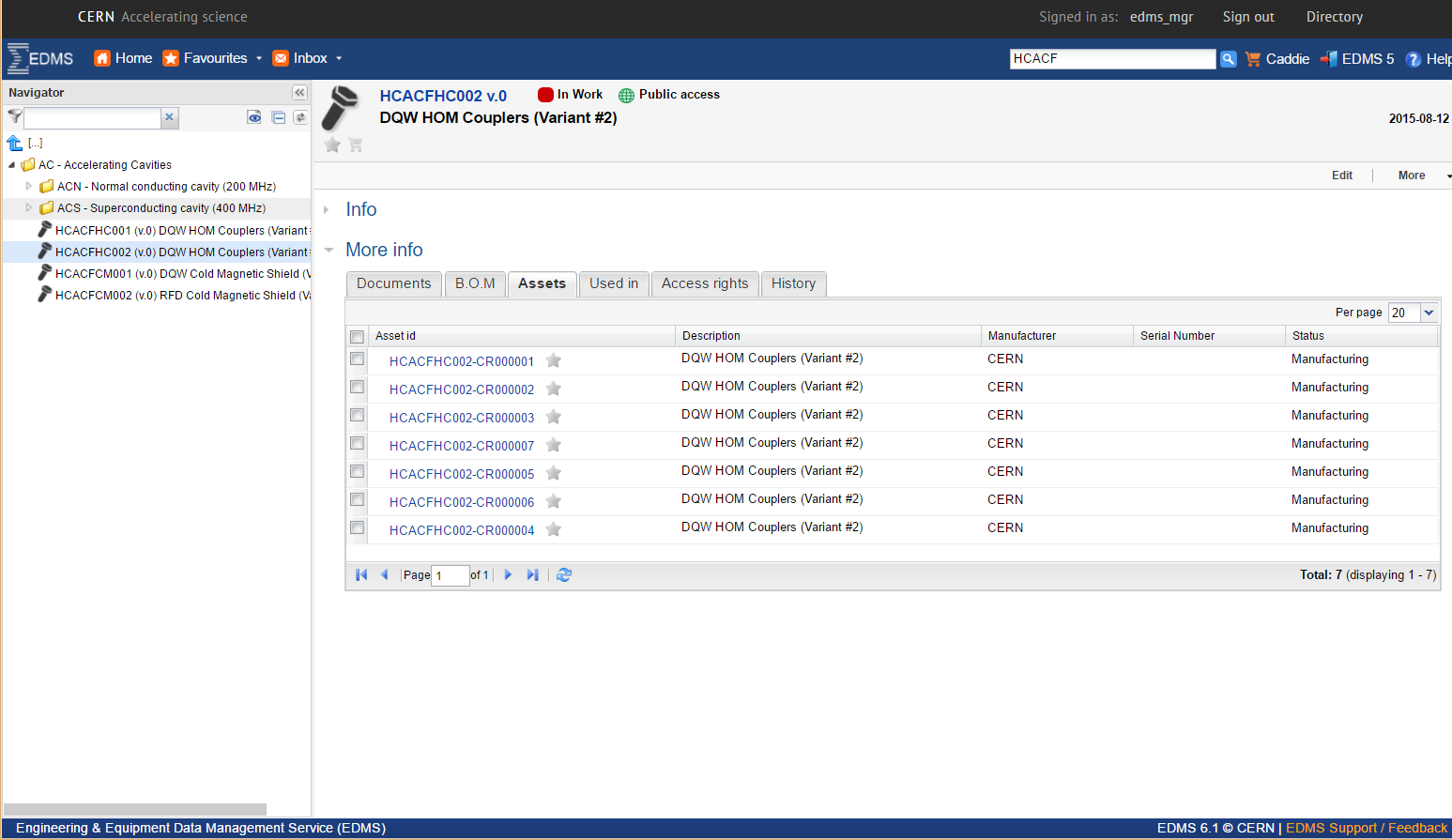

Equipment created for the High Luminosity LHC Work Package 4

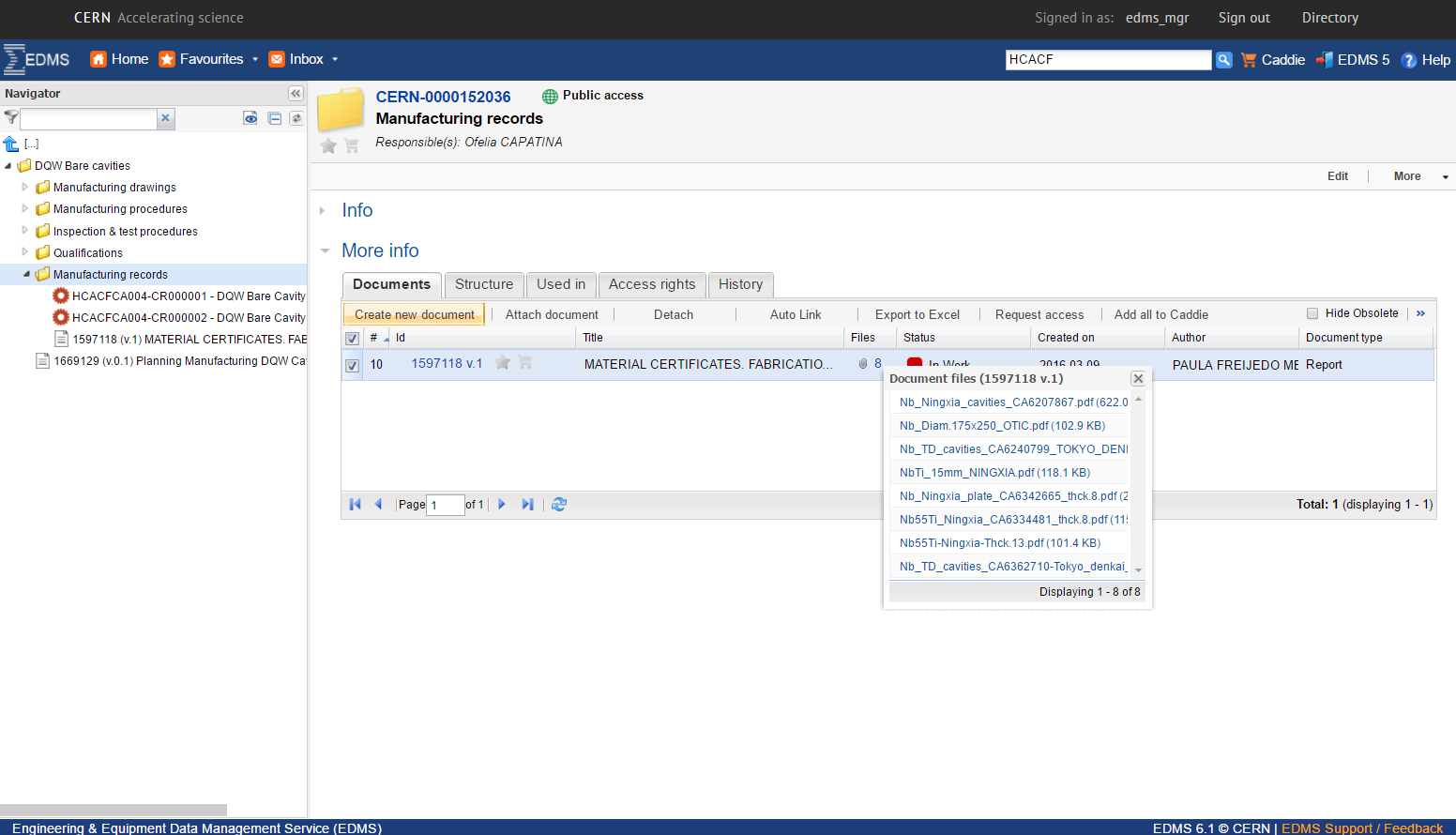

Manufacturing records from equipment produced in Berkeley, USA

Installation

CERN Configuration Managers

The Configuration and Layout (CL) section from the Alignment, Coordination & Engineering (ACE) Group within the Engineering (EN) department ensures that there is a clear and coherent representation of the status of the CERN accelerator complex and projects at a given time; the changes cover the areas related to projects, consolidations and upgrade activities. This is achieved by storing physical layout information and long-term documentation in databases to form a Product Breakdown Structure (PBS), and by managing changes. The PBS aims to describe all components of a project or facility in as much detail as possible, through a clear hierarchical structure of systems. At CERN, documents such as Functional and Engineering Specifications, Space Reservation Requests (SRR), Engineering Change Requests (ECR) and other long term documentation (procedures, technical reports etc.) are stored in the PBS. This documentation is handled centrally by the Configuration team, who ensure the quality of the documents and their circulation to, and approval by, all stakeholders.

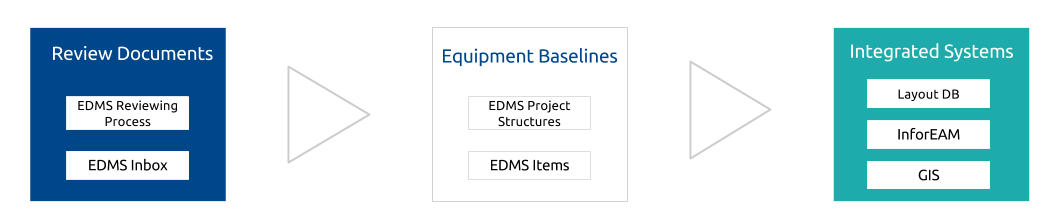

The team uses EDMS as one of its main daily drivers. EDMS allows CERN’s configuration managers to consult the preliminary design specifications and 3D designs of a given component, monitor data about its manufacturing process and then create engineering change requests (ECRs) and orders if needed. All those objects exist in EDMS as documents and benefit from EDMS functionality such as document life cycles, reviewing processes, versioning, project document numbering and access rights management. EDMS Contexts enable the CL section to configure the aforementioned functionality in a meaningful way for their activities.

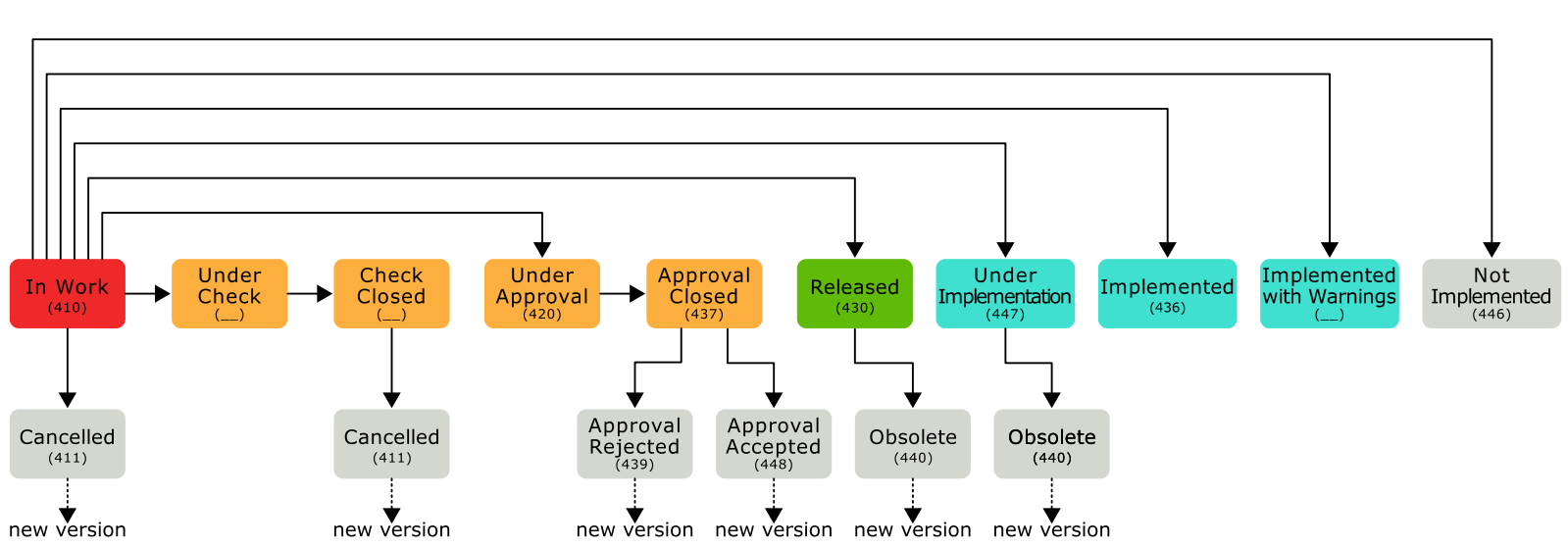

A generalised lifecycle of an ECR at CERN

EDMS allows the CL section to store, version and approve ECR and SRR documentation. As those documents need to be approved by a variety of stakeholders, EDMS' Document lifecycle and Inbox functionality help the configuration managers with the reviewing processes they are in charge of.

The document lifecycle in EDMS used by the CL team

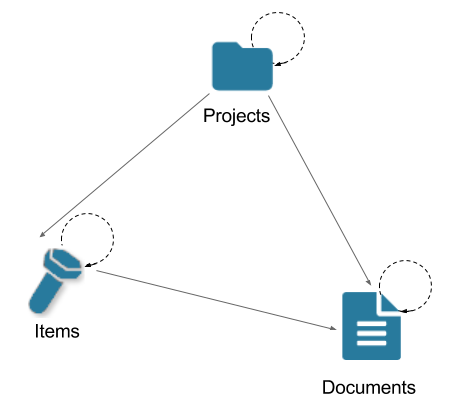

Besides the ECR/SRR processes, the Configuration Managers also maintain hardware baselines for the individual machines within EDMS. The aim of a hardware baseline is to capture a snapshot of the current, installed (or nominal) state of a given machine. Currently in EDMS there are baselines for most of CERN’s large machines such as the LHC, SPS and PS. These baselines contain all the items, equipment and documentation applicable to the operation of the given machine. EDMS facilitates the creation, use and management of hardware baselines via the Project – Item – Document object structure functionality it offers.

EDMS object structure concept

Furthermore, all the baseline equipment and its documentation are visible in CERN’s layout database, thanks to an integration done between the two systems. The LHC Layout database is designed to store all data pertaining to the collider, its components, their layout and their manufacturing as a large unified tool. Thus, allowing CERN’s configuration managers to track ECRs, manage the current state of a machine and know exactly where a given component is installed by using EDMS and the Layout database.

To conclude, CERN’s configuration managers use EDMS and its capabilities to capture the current state of the Organisation’s machines and to approve and manage the changes performed on them. The tool’s structuring and reviewing capabilities are fully exploited by the CL section and their work is then presented at the LHC Injectors and Experimental Facilities Committee (IEFC) and LHC Machine Committee (LMC) for a final approval.

Safety

Occupational Health & Safety and Environmental Protection (HSE)

CERN’s HSE Unit supports the Organization in the implementation and enforcement of its Safety Policy, monitors the implementation and accomplishment of Safety objectives aimed at a continuous improvement of safe working and operating conditions as well as environmental protection.

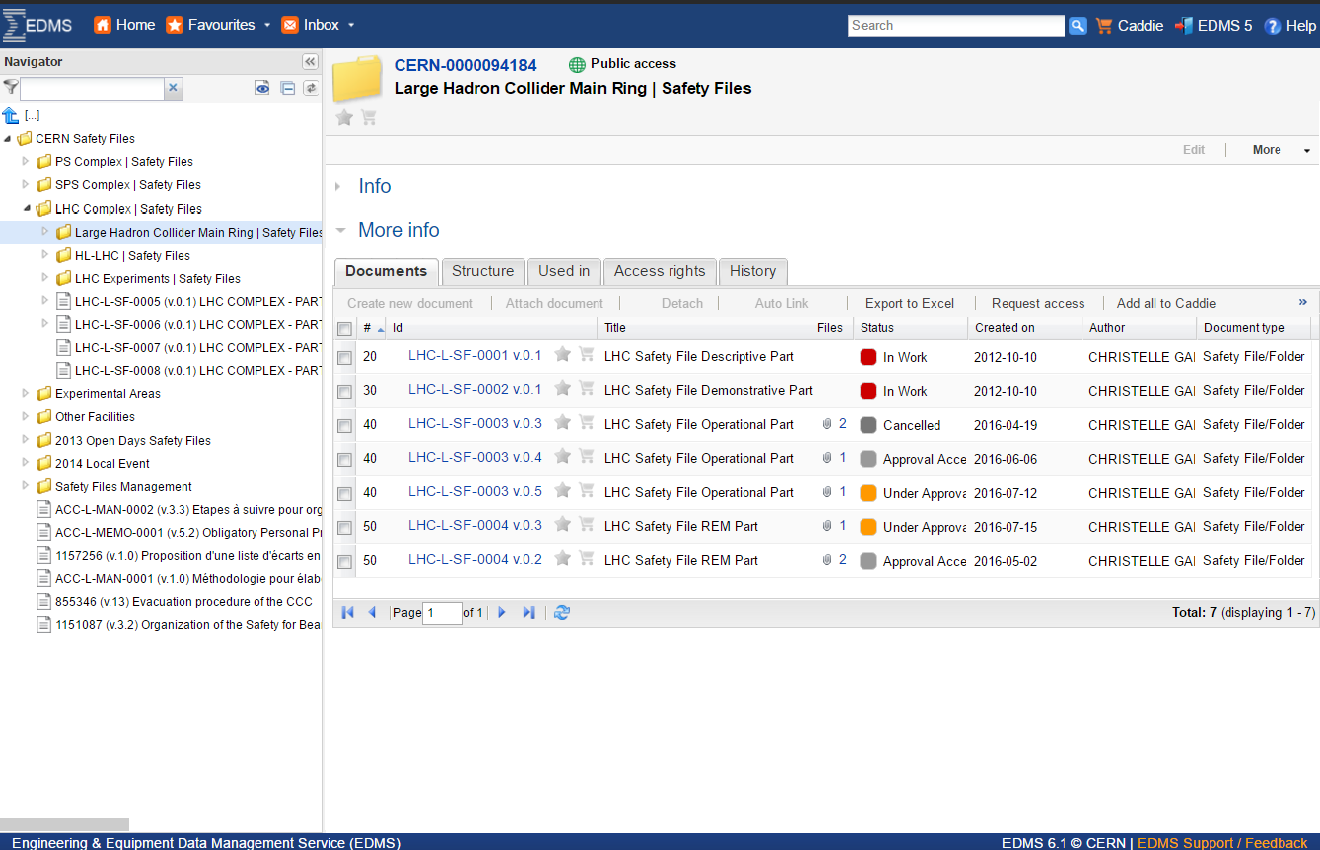

As such, the HSE unit is involved with the PLM process at CERN. The Radiation Protection (HSE-RP) and the Safety Engineering and Environment (HSE-SEE) groups use EDMS as a daily driver for all their procedures and documentation. Documentation within EDMS by HSE includes radiation protection data, CERN’s safety files, evacuation plans and operational documentation. For example, each of CERN’s machines has a dedicated section of safety files. A safety file section has 4 parts – Descriptive, Demonstrative, Operational and an REM (Records, Experience and Monitoring). Those parts taken together provide an overall picture of the safety oriented description of a machine’s operation, an inventory of its operational risks, their potential mitigation and ‘lessons learned’ from operating it.

Last but not least, scheduled safety inspections on CERN’s office buildings, workshops and infrastructure performed by safety inspectors are stored and approved using EDMS. In doing this, CERN’s safety inspectors share their inspections with the whole CERN community. In addition to this, planned electrical cuts are also announced via EDMS documents.

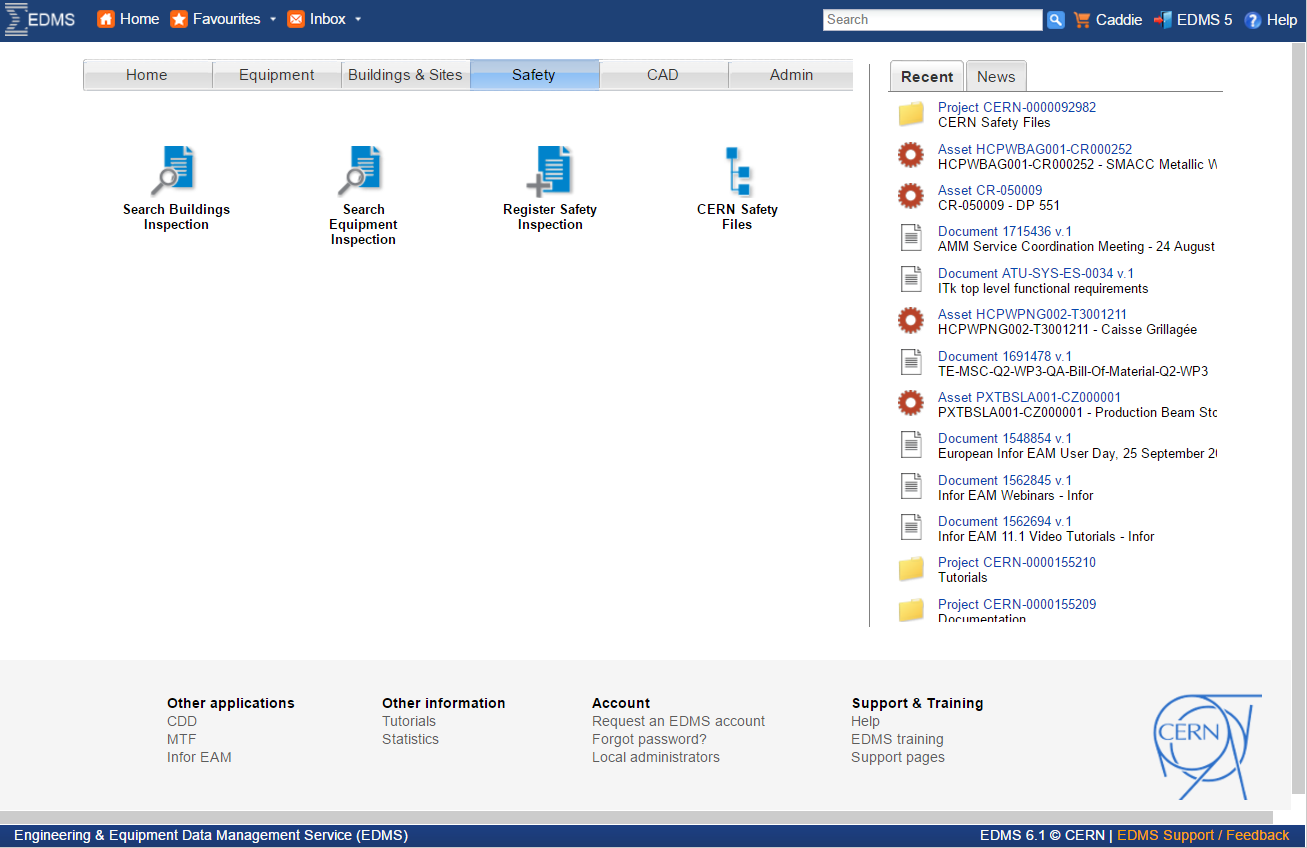

The Safety tab in EDMS and the CERN Safety Files structure, managed by HSE and CERN’s safety officers

LHC’s Main Ring safety files in EDMS

Commissioning

EDMS is a key component for CERN during the commissioning and client acceptance phase of the Organization’s important projects. Benefitting from the tight integration between Infor EAM and EDMS, CERN stakeholders use EDMS for the upload of test reports, electrical tests, schematics, layouts, manuals and validation documents, amongst many others, in the form of documents that are then attached to the physical pieces of equipment they describe. Furthermore, and once attached, these documents are readily available and used by the CERN Control Center and maintenance personnel in the case an alarm flags up a piece of equipment up for an inspection.

Notable examples of the commissioning work done in EDMS is the large number of electrical test reports and electrical schematics uploaded to EDMS by the EN/EL group. The group uses EDMS to store electrical test data and the latest schematic layouts relevant to equipment, functional positions and physical locations. As such, EN/EL make sure that this data is widely available to anyone working on those.

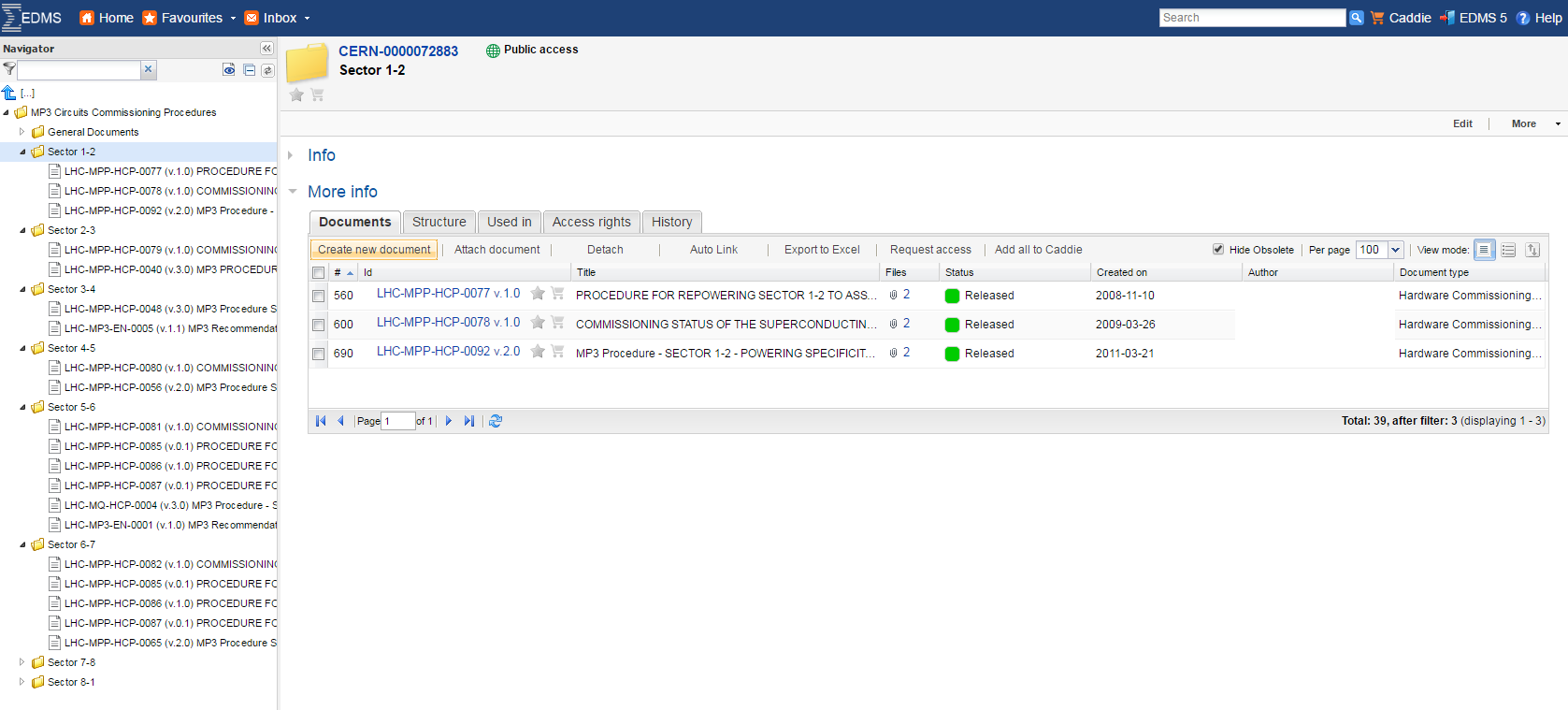

Another example is the Machine Protection and Electrical Integrity (TE/MPE) group, who during the YETS (year-end technical stop) and LS (long-shutdown) breaks perform hardware commissioning projects on the LHC machine protection systems and interlocks. The group collects massive amounts of data from its controls systems about the state of components, their configuration and their performance and then uploads it in EDMS. Afterwards, and benefitting from the Infor EAM integration, the group is available to easily attach the EDMS documents to the corresponding Hardware Commissioning manufacturing workflow steps of a component within MTF.

A third example is the Industrial Controls Systems (BE/ICS) groups, who, during YETS and LSs, perform extensive tests on equipment related to access control and safety systems. These tests are uploaded to EDMS and linked to physical locations, i.e. safety and access zones, or safety equipment in Infor EAM and are used to validate access and safety system integrity. As such, EDMS’ capabilities and its integration with Infor EAM ensure that the LHC and PS’ access and safety systems are up to standards and function as required.

The data generated by stakeholders tasked with commissioning activities is readily available in EDMS and attached to the relevant object. As such, these three examples, amongst others, taken together provide an overview of the initial or current state of a given machine and allow project leaders, project engineers and maintenance personnel to perform their activities in an informed matter.

For HSE-RP activities, please see the Decommissioning section of this page.

The Hardware Commissioning structures and procedures used by the TE/MPE group in EDMS

Operation & Maintenance

EAM Integration

EDMS, as CERN’s official Product Lifecycle Management (PLM) system is tightly integrated with Infor EAM, CERN’s official Enterprise Asset Management (EAM) system.

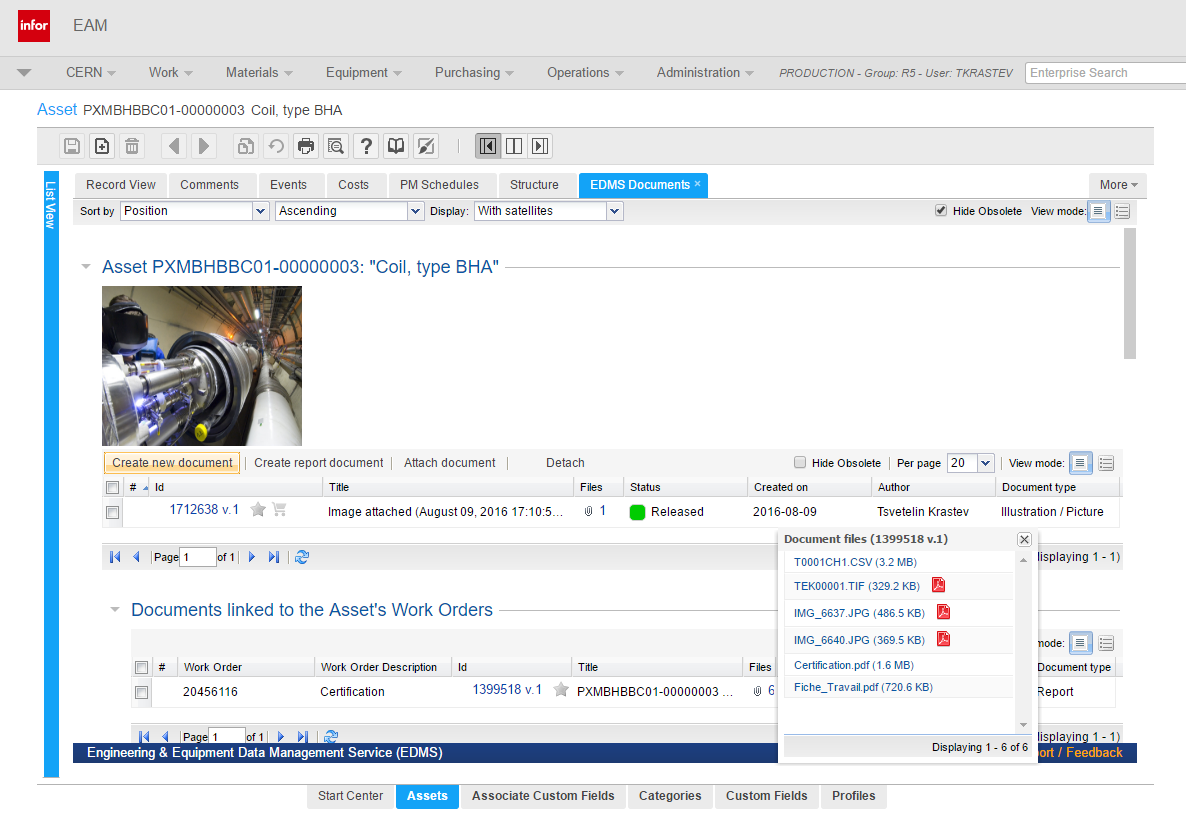

EDMS and Infor EAM together provide an overview of a component, its design, the work done on it and the documentation generated throughout the PLM lifecycle. Both systems display equipment and documents in their native interfaces, as a result you do not have to jump through different systems and browser tabs to work.

EDMS documents can be created from within Infor EAM or Infor EAM objects can be displayed within EDMS as to attach documents to them.

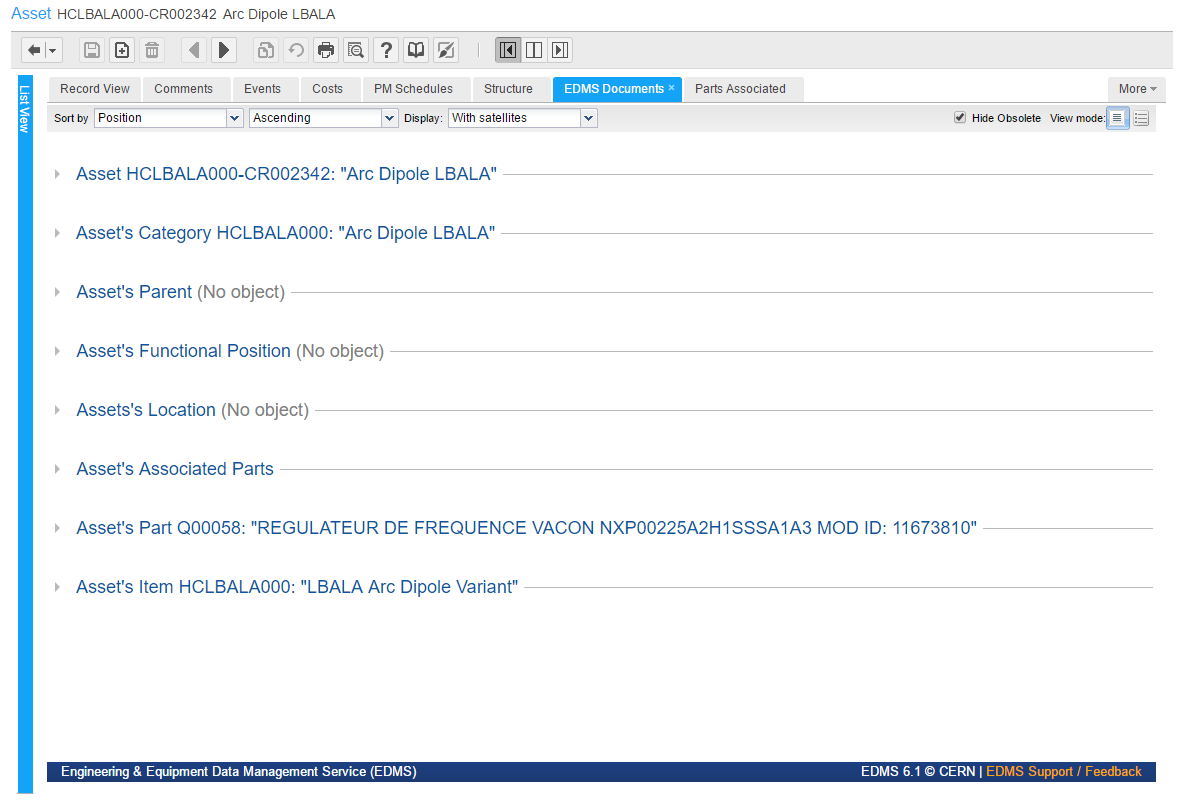

The ‘EDMS Documents’ tab shown within the Infor EAM and EAM Light interfaces offers functionality developed with equipment management in mind. The display can apply a ‘satellite’ perspective, showing attached directly to the object and its related objects. E.g. the documentation linked to the structural hierarchy and the work performed on a piece of equipment can be seen directly from the piece itself.

In addition to this, Infor EAM objects can be attached to EDMS projects, thus allowing for a switch of perspectives depending on the system used – PLM or EAM. On top of that, the system’s search is cross system and as such it can serve as an entry point to EDMS and Infor EAM. Using the Search functionality allows a user to locate not only documentation and designs but also the related physical equipment, locations and or functional positions (coming from Infor EAM).

The Magnetic Measurements (MM) section within the Magnets, Superconductors and Cryostats group (MSC) of the Technology Department (TE) is a notable example of the use of both EDMS and Infor EAM together and making the best out of the integration between the systems.

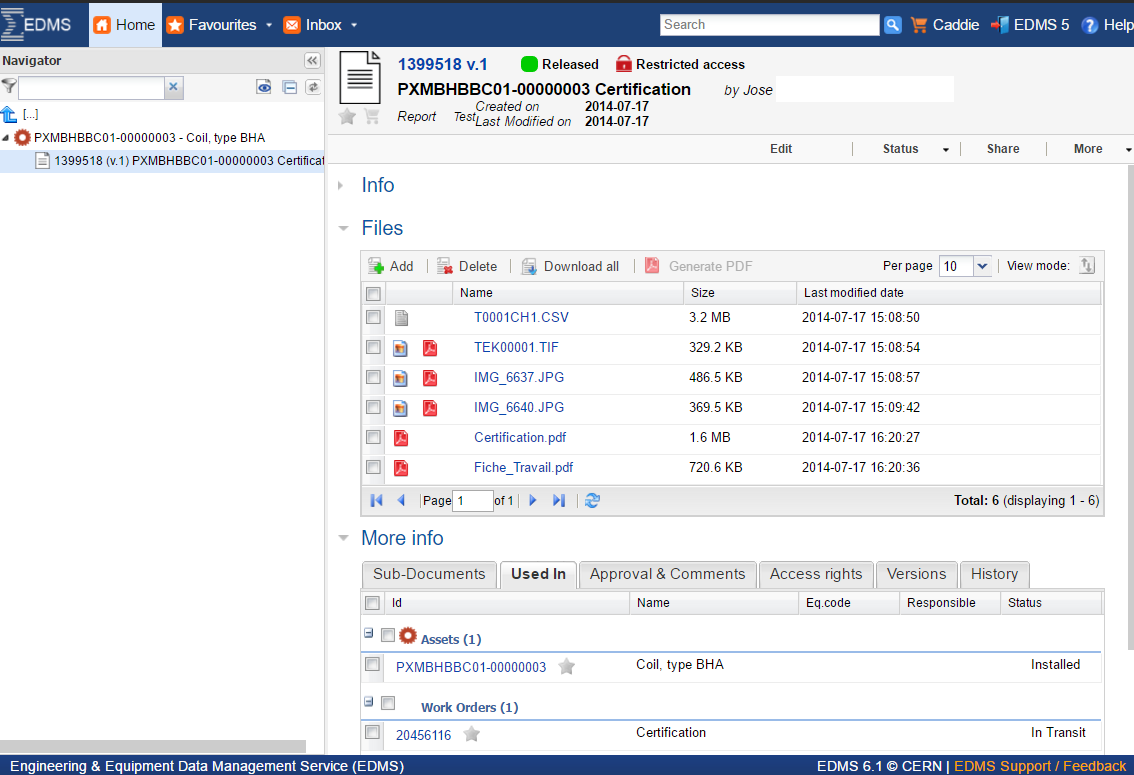

The MSC group registers all magnet components into Infor EAM, then the MM section performs measurements and tests on them via Work Orders. The results of these work orders are thoroughly described in EDMS documents attached to the Work Orders, which are, in their turn, attached to the magnets. All the three objects are transversally visible in both EDMS and Infor EAM, with EDMS providing a PLM centred perspective and Infor EAM an equipment centred one. In addition, the EDMS Documents list in Infor EAM/EAM Light displays photos as thumbnails, this allows a visualisation of a component or the work done on it.

The document in EDMS and the Infor EAM objects it is attached to

The EDMS documents tab from the same component in Infor EAM with the Satellites view with a thumbnail

Decommissioning

EDMS and TREC

HSE-RP manages the radioactive waste coming from CERN installations thanks to EDMS & TREC. These tools support follow-up of the reception, classification, interim storage, treatment, radiological characterization and processing of radioactive waste as well as the traceability of their disposal towards the final repositories, both in Switzerland and in France.

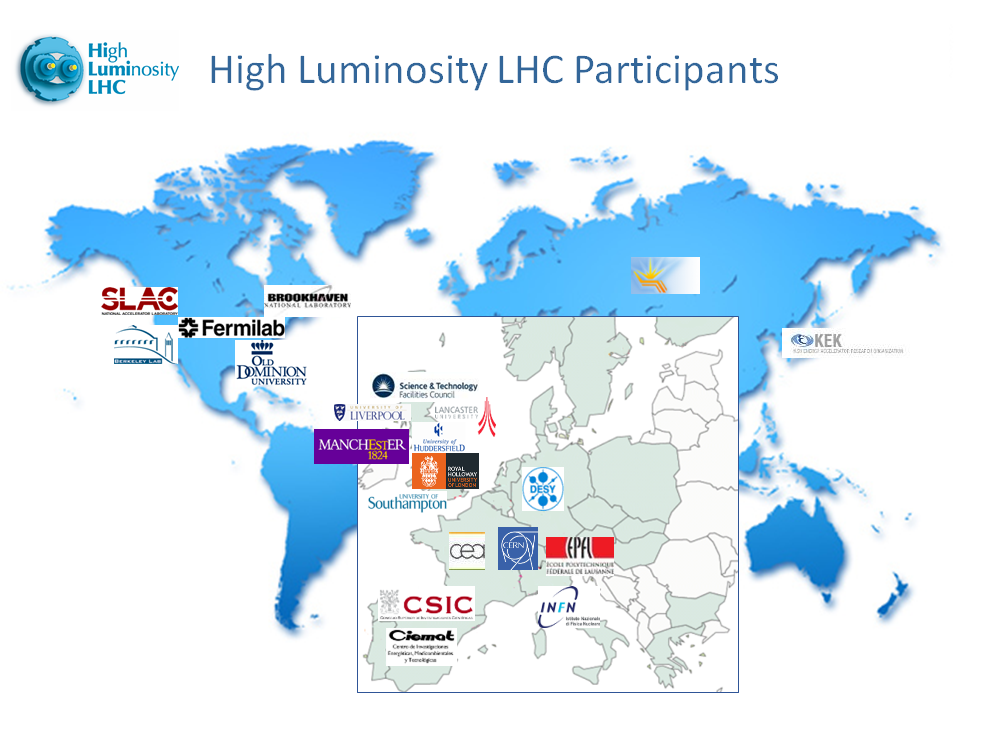

Furthermore, technicians responsible for the decommissioning phase make sure that any piece of equipment that goes out of CERN’s tunnels is analysed using dedicated devices. These machines then upload the analysis results automatically to EDMS. This analysis document is then attached to a radioactive protection measurement work order in Infor EAM, which in its turn is linked to the piece of equipment measured.

A TREC measurement performed on an asset, as seen from EDMS